MartinMechanic sets new standards in production with innovative plastic bobbins

MartinMechanic is pleased to announce the launch of a state-of-the-art production process for plastic bobbins. The use of advanced automation technologies and robotic solutions significantly increases manufacturing efficiency and quality.

The new plastic bobbins are separated from bulk material, with the orientation of each bobbin being carefully checked. A robot removes the bobbins and places them on a joining mandrel before pins are cut from a continuous belt and precisely pressed in.

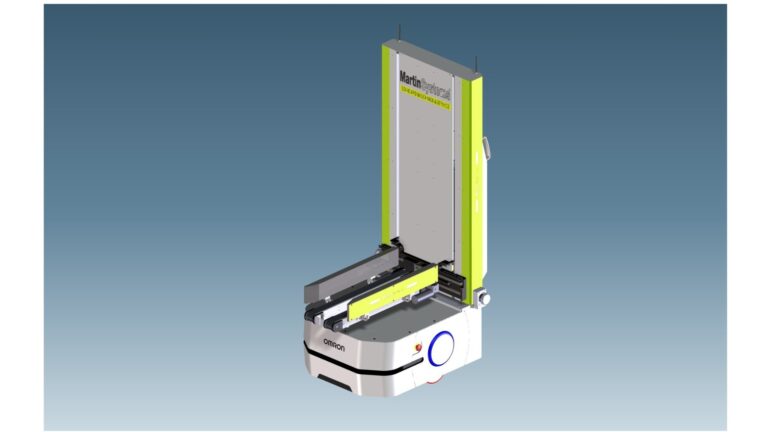

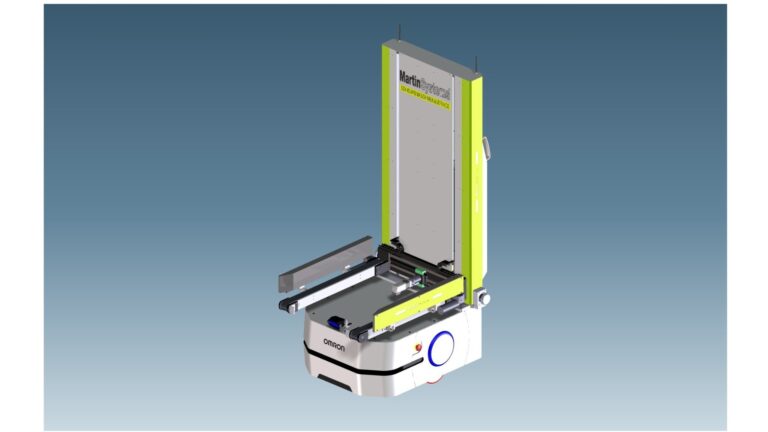

After production, the flawless (IO) parts are either sorted on workpiece carriers (WT) or ejected into bulk bins. Both options allow for easy handling and further processing. The workpiece carriers and bulk bins are fed via a conveyor belt, with the possibility of being loaded by an autonomous mobile robot (AMR).

With this new production line, MartinMechanic is taking another step towards Industry 4.0 and showing how modern technologies can revolutionize manufacturing. Customers benefit from attractive conditions and punctual deliveries, while employees benefit from exciting tasks and an improved working environment.