TelMAX – Efficient Torque and Condition Monitoring for Drivetrains

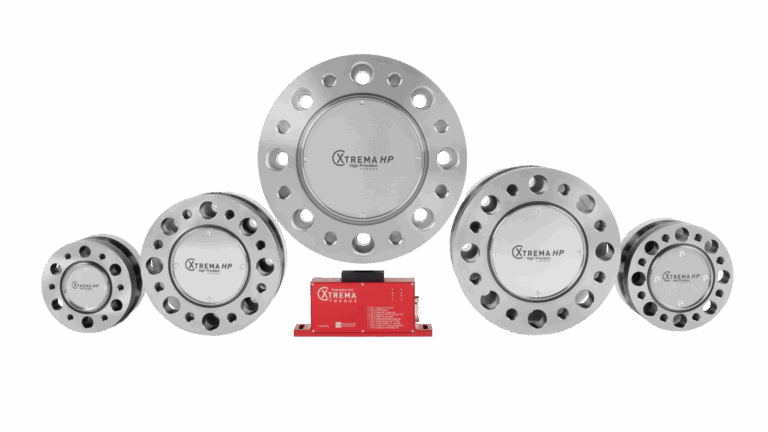

TelMAX is the innovative torque measurement system from MANNER Sensortelemetrie for dynamic monitoring of drivetrains, gearboxes, pumps, motors, cardan shafts and similar machinery. It enables cost-efficient, contactless torque measurement without soldering or gluing, significantly simplifying installation and reducing downtime.

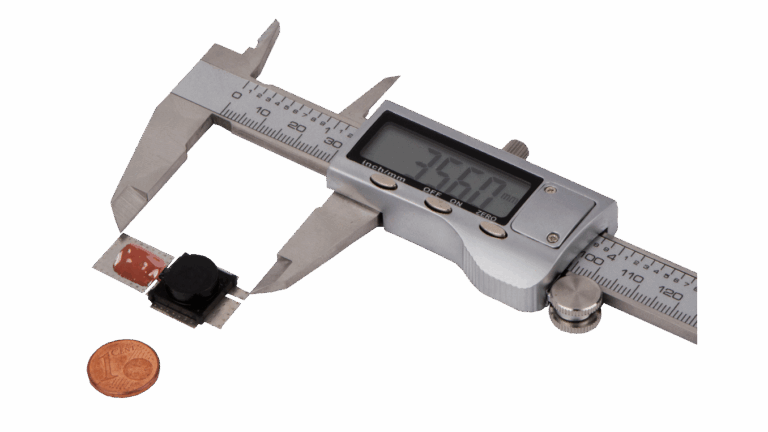

At the core of TelMAX is a telemetric torsion sensor based on strain gauge technology, which is mounted directly onto the rotating shaft using micro-welding technology. This preserves the shaft material and allows the sensor to be installed and operational within minutes – without complex preparation or curing times.

The measured data is transmitted wirelessly from the rotating sensor to the stationary receiver unit. The evaluation electronics provide robust interfaces such as analog voltage, 4–20 mA current and CAN, enabling easy integration into control systems and automation environments.

TelMAX offers high signal quality and dynamic performance, making it ideal for capturing fast load changes and complex dynamic processes. Its robust design ensures reliable operation even in harsh industrial environments where conventional strain gauge bonding techniques are impractical.

Typical applications include condition monitoring and predictive maintenance, load and efficiency measurement, retrofit projects on existing machinery, and analysis of real operating load profiles. TelMAX provides a practical, flexible and future-proof solution for torque and condition monitoring in modern industrial and Industry 4.0 applications.