Unplanned machine downtime, rising maintenance costs and the ongoing pressure to improve product quality are among the biggest challenges in industrial manufacturing. Predictive maintenance has become an effective approach to meeting these demands.

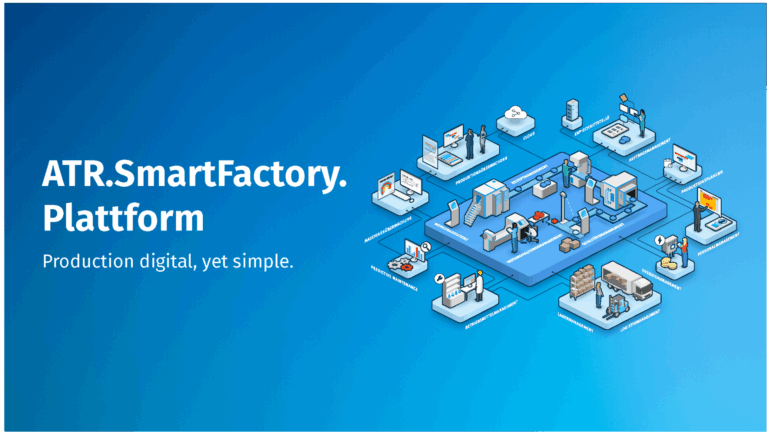

Using technologies such as real-time monitoring and AI-driven data analysis, the ATR.SmartFactory.Plattform module helps you detect potential issues early and take targeted action. The result: reduced downtime, higher product quality, optimised use of resources and significant cost savings.

Benefits at a glance:

• Maximised efficiency and productivity

• Improved product quality

• Faster implementation and adaptation

• Future-proof production processes

• Reduced costs and optimised use of resources

• Early fault detection

• More precise control and optimisation

Meet our experts at all about automation Friedrichshafen and discover the future of production. We look forward to seeing you!

Unplanned machine downtime, rising maintenance costs and the ongoing pressure to improve product quality are among the biggest challenges in industrial manufacturing. Predictive maintenance has become an effective approach to meeting these demands.

Using technologies such as real-time monitoring and AI-driven data analysis, the ATR.SmartFactory.Plattform module helps you detect potential issues early and take targeted action. The result: reduced downtime, higher product quality, optimised use of resources and significant cost savings.

Benefits at a glance

• Maximised efficiency and productivity

• Improved product quality

• Faster implementation and adaptation

• Future-proof production processes

• Reduced costs and optimised use of resources

• Early fault detection

• More precise control and optimisation

Meet our experts at all about automation Friedrichshafen and discover the future of production. We look forward to seeing you!

For more details, download the accompanying PDF.