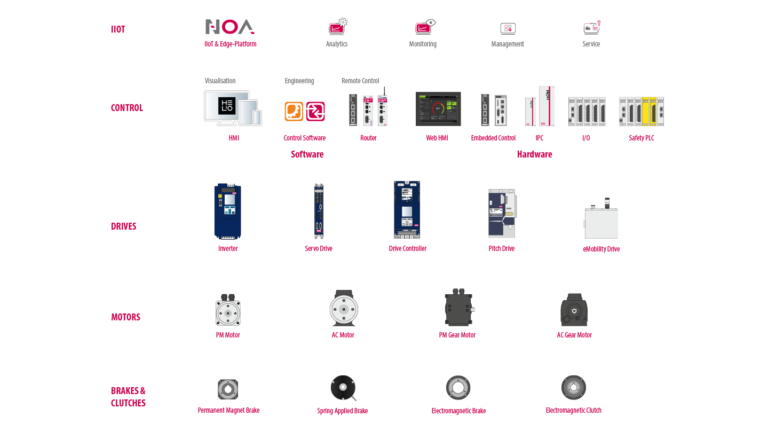

The open automation and IIoT platform ‘NOA’ – Next Open Automation – enables users to flexibly control and operate their machines and also to intelligently utilise and analyse their machine data. This reduces downtime, lowers costs and increases efficiency. Apps such as machine learning, monitoring and HMI solutions can be easily integrated.

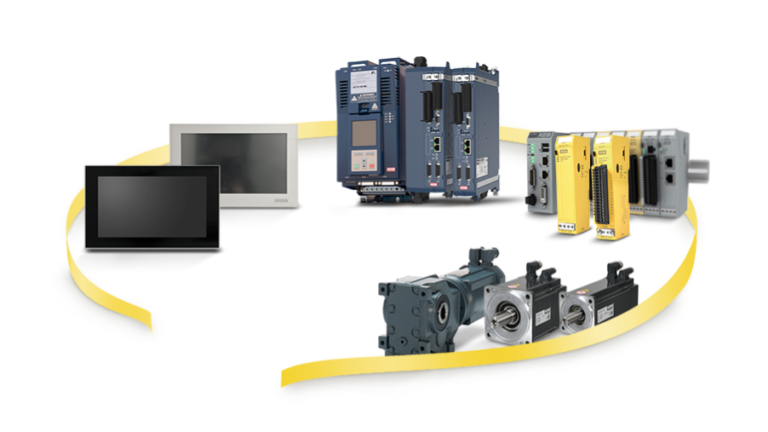

Machine and plant manufacturers use NOA to design customised automation solutions based on open systems. KEB offers a modular basic kit that can be expanded with customer-specific and third-party apps – for your own applications and those of your customers. NOA is based on Linux and container technology and functions independently of hardware as an automation platform as a service (APaaS). The focus is on data acquisition, visualisation and processing.

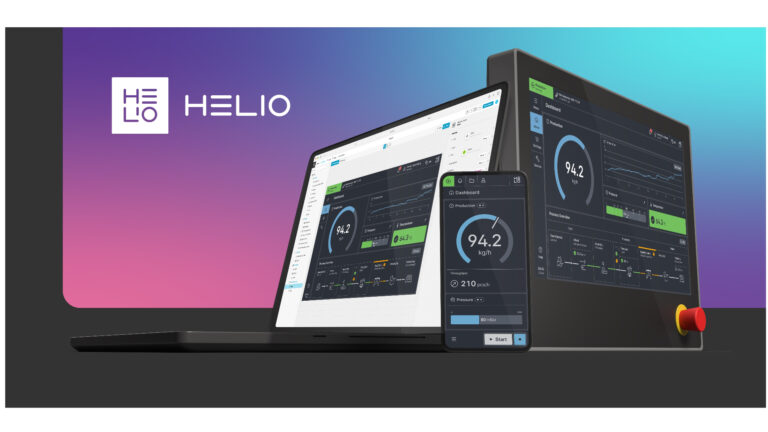

NOA’s applications include predictive maintenance. Thanks to the automation platform, machines can be monitored and maintenance times predicted. This makes maintenance plannable and minimises downtime. Condition monitoring is particularly efficient thanks to the centralised and comprehensive evaluation and visualisation of machine data. In the NOA portal, users can design their own dashboards according to their requirements using the Dashboard Builder. Device and fleet management enables centralised administration of all devices, including over-the-air updates. Apps can be integrated directly as containers – no app store is required.

NOA is available as a white label solution. This enables OEMs to create new business models by providing their customers with an automation platform in addition to their machines. Digital services such as predictive maintenance or condition monitoring, which can be offered as add-ons, increase the value of the machines. Intelligent alarming and remote maintenance are also use cases for NOA.