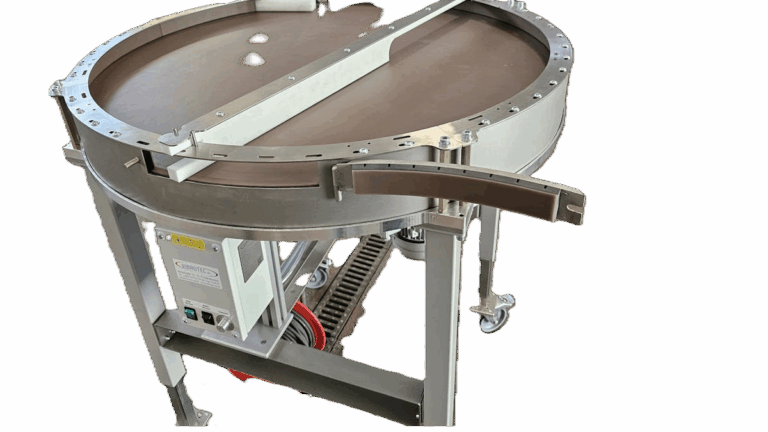

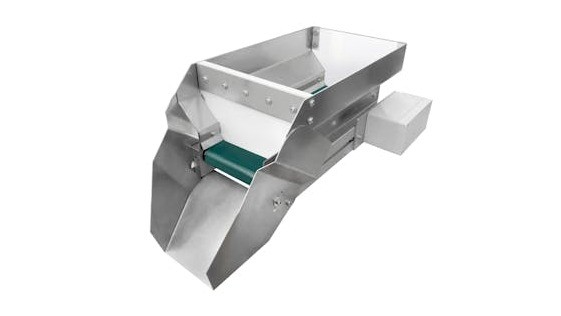

With our new conveyor belt inspection system, you can reliably and accurately detect and sort parts from 5 to 100 mm at belt speeds up to 30 m/min. The Keyence IV4 AI camera checks position and quality in real time. Defective parts are ejected contactlessly after just 50 mm (incorrect position) or 300 mm (quality defect) using targeted bursts of air – good parts continue unimpeded. No mechanical parts, no wear, and maximum repeatability. Perfect for automotive, electronics, medical technology, and packaging. Made in Germany