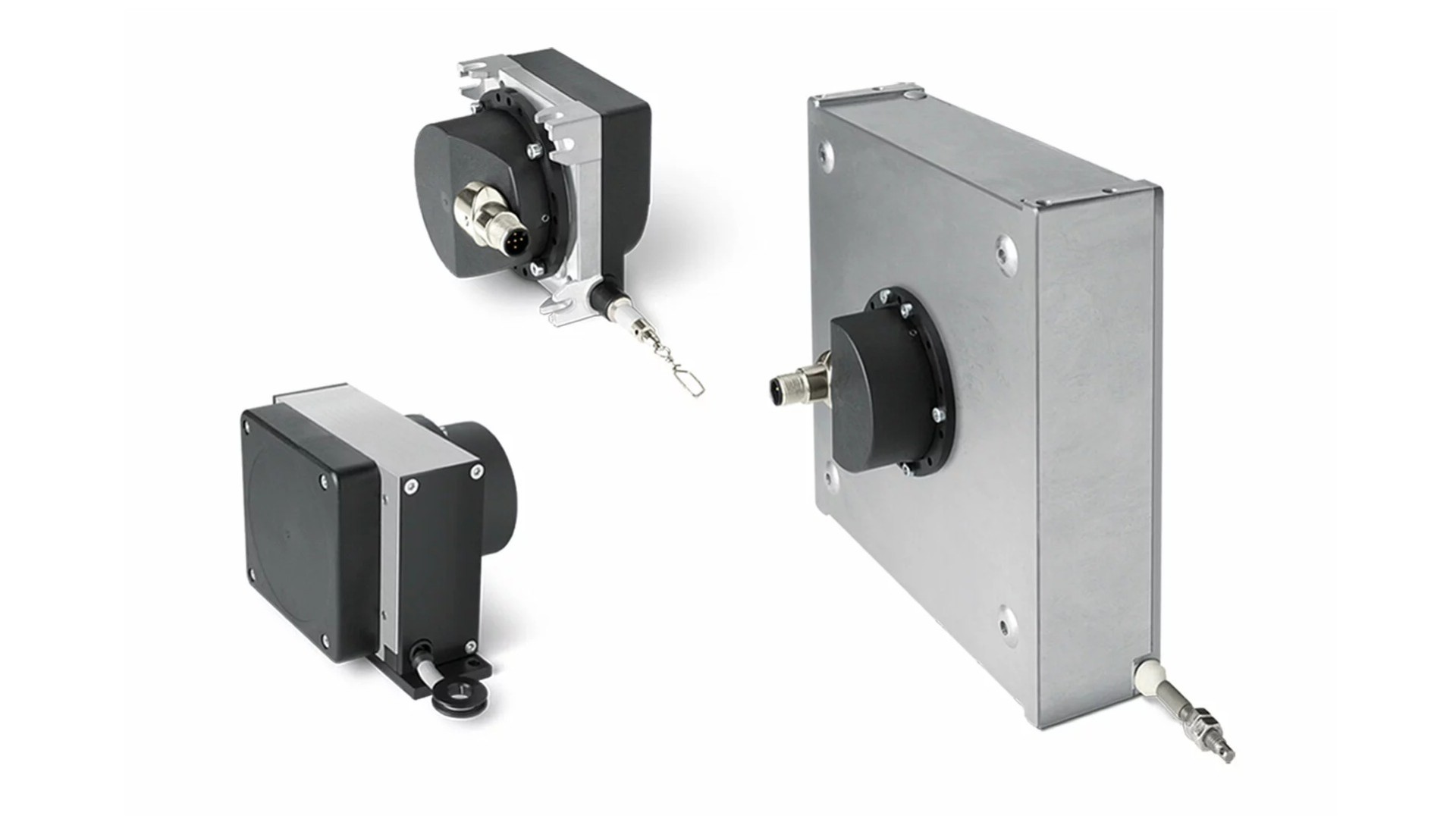

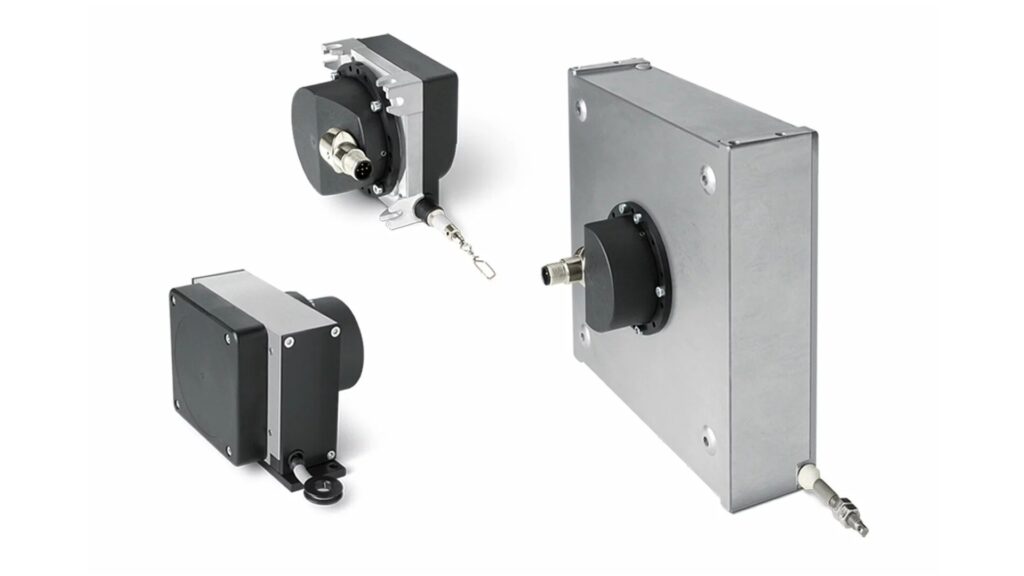

Compact and powerful: Up to 25 percent slimmer

The new generation of draw-wire encoders is characterised by an intelligent and reliable housing design. This protects the wear-free electronics and is the robust backbone of the sensors. The impact-resistant, toughened plastic housing can withstand not only a wide range of fluids, but also direct sunlight (UV radiation) over the long term. Protection class of IP67 or, as an option, IP6K9K, high resistance to shocks and vibration, and E1 certification according to UN ECE R10 by the German Federal Motor Transport Authority are just some of the key features of these draw-wire encoders. All these functions are integrated without affecting the compact design. The sensors are up to 25 per cent slimmer than their predecessors and are therefore perfect for integration into machines with limited installation space.

Robust mechanics meets smart sensor technology: NEO for challenging tasks up to 15 m

The new NEO series will be available as the SG31NEO with a measurement length of up to 3.2 m, the SG61NEO for up to 6 m, the SG121NEO for up to 12 m, and the SG150NEO for up to 15 m. The sensors are based on the proven draw-wire mechanics of SIKO. The draw-wire mechanics known for years for their especially high operational performance in mobile machines have important features and functions to allow them to adapt to tough conditions of many different sorts. In addition to a wide choice of wires, the sensors have options for avoiding ice formation, many wire fixing variants, and proven sealing and temperature architecture, which is necessary for them to work reliably at -40°C and in permanent wet conditions for many years.