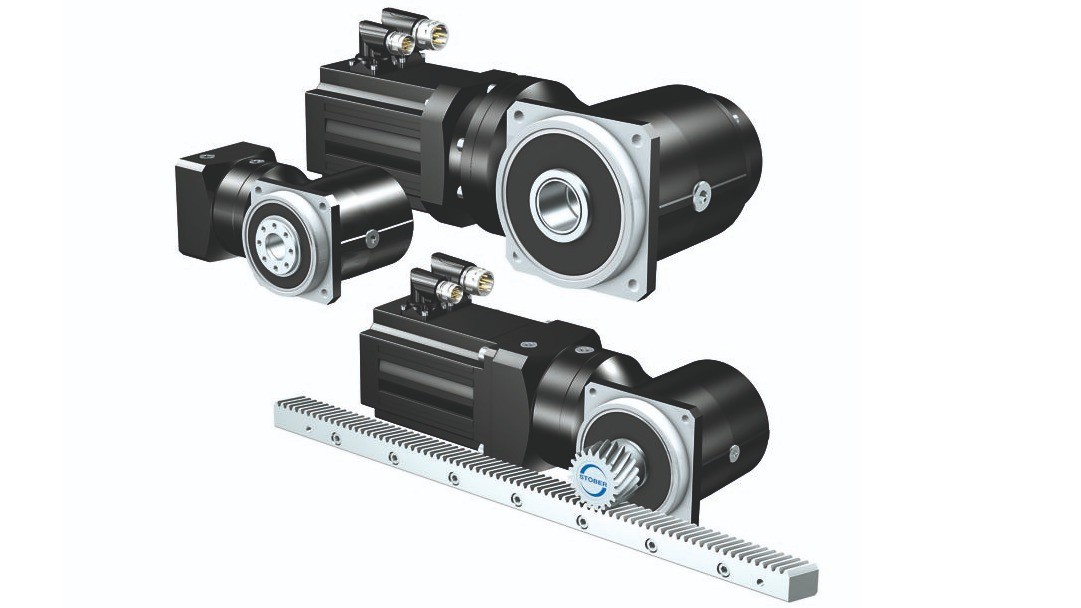

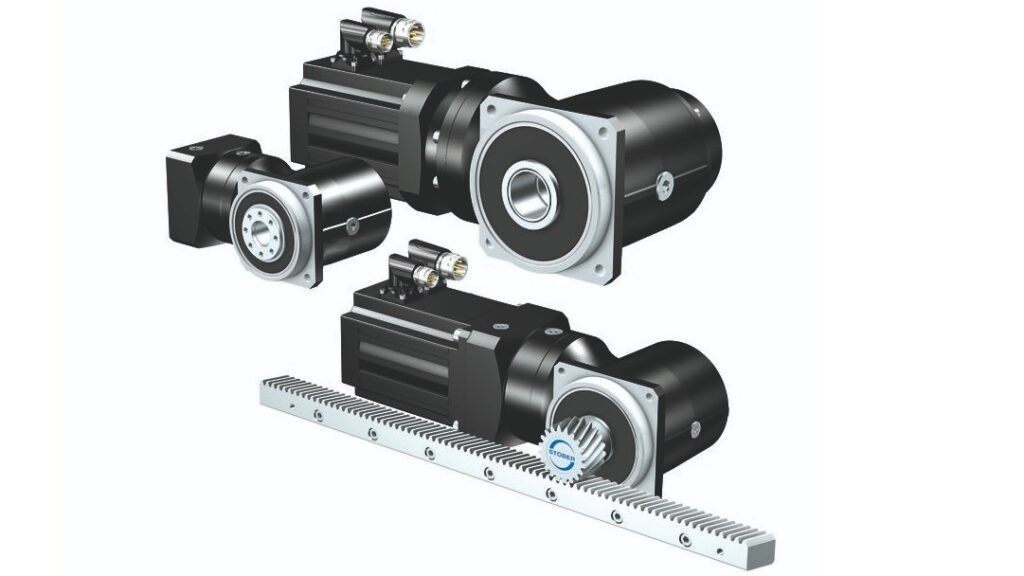

Compared to multi-stage variants, one-stage right-angle servo gearboxes have a more compact design and higher energy efficiency due to the reduced number of components.

The new one-stage version is available in gear ratios 2 and 4. In combination with the compact STOBER planetary gearboxes, solutions consisting of multi-stage gearboxes with ratios from 6 to 400 can be implemented. The previous gear ratio range has therefore more than doubled.

The KS right-angle servo gearbox features robust bearing technology, high-quality gearing technology and very high torsional stiffness. This makes it perfect for demanding applications with high dynamics.

Thanks to low-friction bearing technology in the input, the KS gearbox achieves higher speeds across all variants than many competitors that rely on preloaded tapered roller bearings. In addition, the nominal torques have been increased by up to 20 percent. In combination with the smaller gear ratios, significantly higher output speeds are possible.

The two- and three-stage gearboxes can be combined with various STOBER motors via direct attachment. Thanks to the space-saving drive, operators benefit from less weight in addition to high torque and the resulting increased power density. The mass moment of inertia of the gearbox is lower due to the absence of the motor adapter, meaning that the full dynamics of the drive can be used.