With STEIN Link, we have developed an innovative shuttle system that makes internal material flow more flexible and efficient. Our focus is on maximum adaptability, easy integration, and future-proofing—features that are crucial for modern assembly and logistics processes.

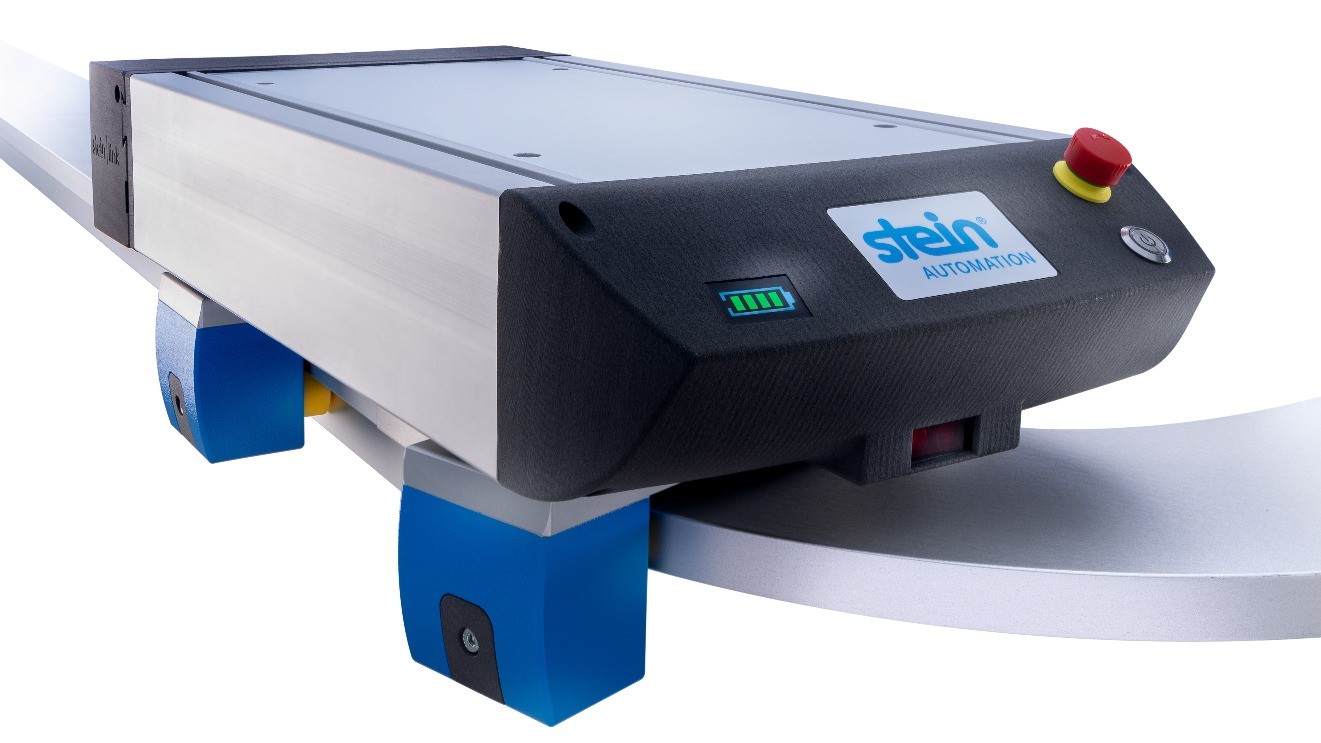

Our system transports workpiece carriers, crates, or customer-specific superstructures with a payload of up to 80 kg at speeds of up to 50 m/min – directly on the shuttle. Thanks to a robust aluminum T-profile, we ensure high tilt stability and smooth running even with off-center loads.

A key advantage is the wireless power supply: our shuttles do not require power rails or power supply along the route. Replaceable batteries ensure the power supply, and when the charge level is low, the shuttle automatically drives to the exchange station. We enable battery replacement manually or automatically. A battery management system continuously monitors the charge status and ensures maximum availability.

We use RFID tags that define logical sections for position and route control. Central software regulates traffic flow, entry permissions, and speed—depending on route occupancy and priorities. In addition, proximity sensors on our shuttles ensure gentle braking when obstacles are encountered.

We have designed STEIN Link to be modular: switches, curves, lifts, and locks can be easily added. Installation requires only a few screws and can even be done under the ceiling to save space. This makes our system particularly suitable for retrofit applications or systems with frequent layout changes.

The result is a scalable, low-maintenance, and future-proof conveyor system with minimal cabling. With STEIN Link, we help companies make their processes more efficient, sustainable, and flexible—an innovative contribution to the factory of the future.