Prevent bearing damage instead of ‘just’ predicting it!

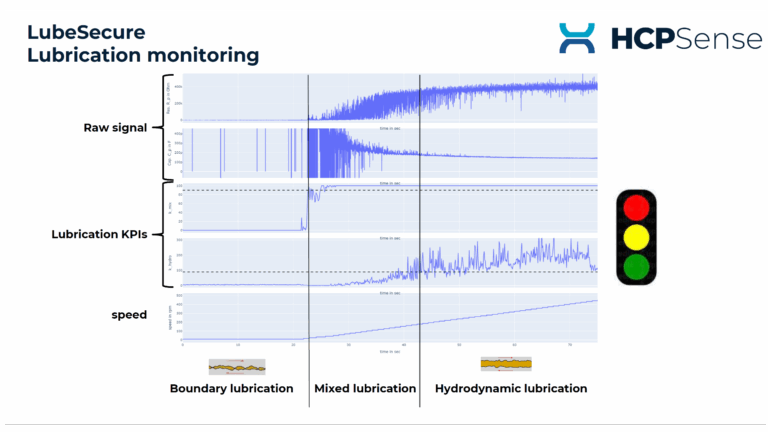

Predictive maintenance becomes resilient maintenance. With our measurement technology, bearings can be operated with optimum energy efficiency without risking damage, and the lubricant can be used until its actual end of life. Our vision is to enable our customers to build “even better” – i.e. more efficient and reliable – equipment and to operate them at their optimum.

HCP Sense, a spin-off from TU Darmstadt, offers a simple and economical solution for measuring bearing loads and monitoring lubrication. This information opens up new opportunities for equipment manufacturers and operators, e.g. for digital business models.

Load and lubrication data are essential for predictive maintenance and for optimizing manufacturing processes. In discussions with equipment manufacturers and plant operators, we have recognized that the effort required for adaptation designs is a major obstacle to the integration of sensors. For this reason, we have developed a patented measuring method that turns conventional bearings into sensors and requires only minimal design adjustments. For the user, it is therefore very easy and economical to integrate our sensor technology into existing designs.

We would be happy to advise you on the beneficial options for using our sensor bearing in your applications. For plain and roller bearings!