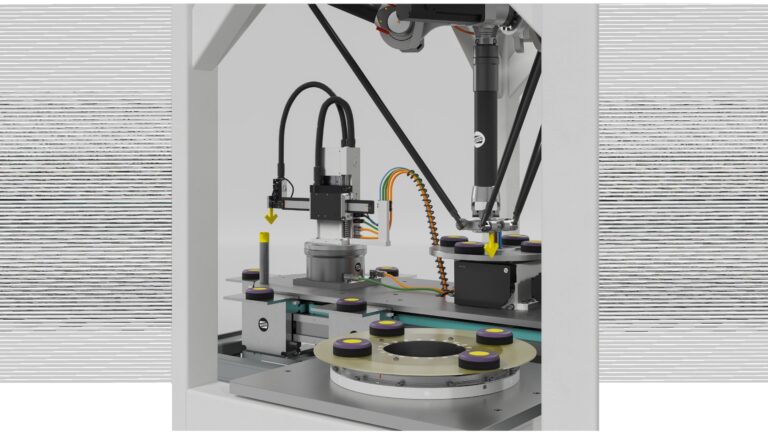

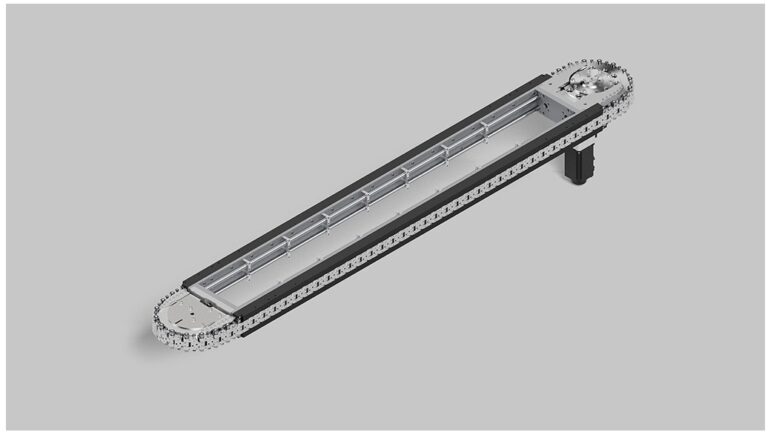

For high-speed installation, the HP 70 Pick & Place Module from WEISS demonstrates its strengths with a maximum speed of 4 m/s. The working space is relatively large thanks to the horizontal stroke of up to 325 mm. In combination with an acceleration of 40 m/s2 and short cycle times, the high-speed motions exert high loads on the cable connections and the cable conduit. This is why WEISS has optimized this module. From now on, a flat ribbon cable will protect the media hoses. This cable combines four pneumatic lines and four signal lines. It is considerably more stable under motion, quieter, and less susceptible to wear. The automation specialist tested the new assembly in endurance tests over a period of several months. The module consisting of flat ribbon cable including the eight media lines is available as an option or spare part. Any HPs already in use can be retrofitted by WEISS Service. The compact module is a mere 60 mm wide and weighs only 9 kg. The 70-mm vertical stroke never extends beyond the body of the component. It is produced using kinematics. This eliminates vertical linear motor movement – a major benefit in the cramped conditions of assembly lines. The Pick & Place Module is designed to save space and is able to map different process stations in a very confined area. This creates a functional subsystem, especially in combination with WEISS rotary indexing tables or linear transfer systems. It is integrated into the system as a whole using the plug-and-work principle. HP 70 features free programmability. The WEISS Application Software W.A.S. helps with integration. The control package simplifies programming and operation. System operators and users do not require any in-depth control knowledge.