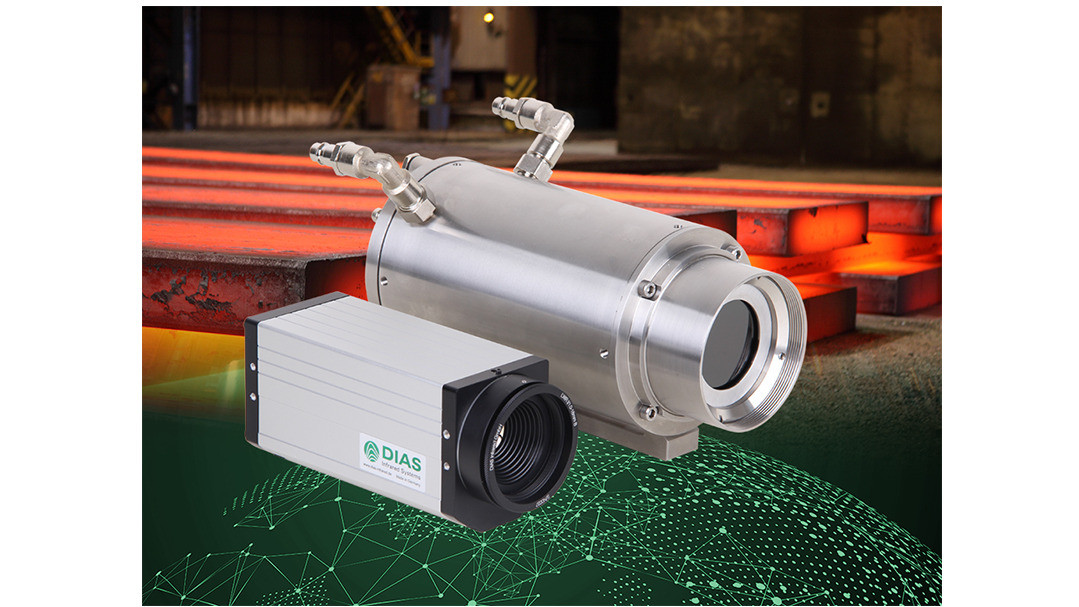

The proven PYROVIEW thermal imaging camera series from DIAS Infrared has now been expanded with two new models: PYROVIEW 1600N and PYROVIEW 1920N. The PYROVIEW family includes a wide range of camera types that differ in temperature and spectral ranges, pixel resolutions, optics and housing designs, allowing optimal adaptation to diverse industrial applications. All models feature a high‑speed Ethernet interface that enables loss‑free, extremely low‑latency real‑time data transmission at the maximum frame rate. In addition, the specially developed PYROSOFT software packages (online/offline) support image display, analysis and integration into process control systems.

The new PYROVIEW 1600N and 1920N models are designed for non‑contact temperature measurements between 650 °C and 1800 °C, making them ideal for demanding applications in the metallurgical and glass industries. Operating in the near‑infrared spectral range between 0.8 µm and 0.9 µm, they significantly reduce measurement errors caused by emissivity variations.

To meet the high spatial resolution requirements typical for these applications, both models use advanced HD Si sensor arrays:

PYROVIEW 1600N: 1600 × 1200 pixels

PYROVIEW 1920N: 1920 × 1080 pixels

Both cameras achieve a frame rate of 25 frames per second. A selection of standard, wide‑angle and telephoto lenses with motorized focus allows easy adaptation to different measurement distances and fields of view.

The PYROVIEW compact+ devices feature a robust IP54 aluminum housing, making them suitable for universal use in industrial environments.