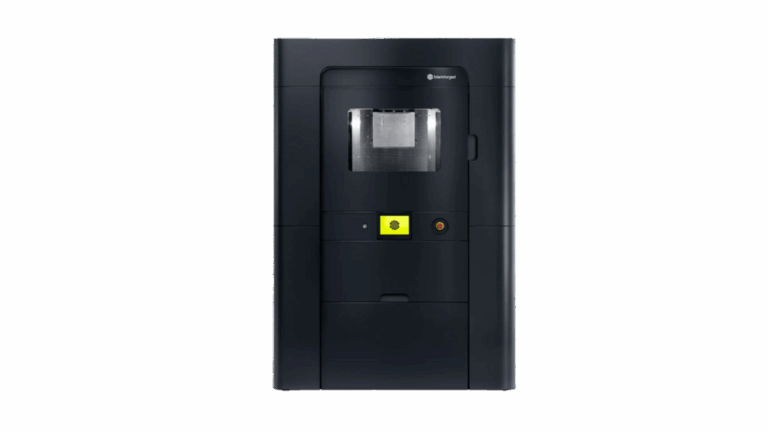

Markforged FX10

NEW: Plastic × Metal combined in one 3D printing system!

The Markforged FX10 revolutionizes additive manufacturing by uniting plastic and metal 3D printing within a single system. Its generous build volume enables the production of large, high‑precision parts from materials such as Onyx and stainless steel. Thanks to its modular architecture, both polymer and metal components can be produced flexibly, making the FX10 the most versatile tool in your manufacturing workflow.

Build Volume

375 × 300 × 300 mm

Technology

FDM with continuous fiber reinforcement and FDM Metal

Layer Height

125–250 microns

Materials

Onyx, Onyx FR, Onyx ESD, Nylon

Continuous fibers: Carbon Fiber, Carbon Fiber FR

Metals: 17‑4 PH Stainless Steel, 316L Stainless Steel

Ideal for:

High‑strength components with demanding stability requirements

Functional prototypes in both plastic and metal

Single metal parts

Robust production tools

Replacement of machined components