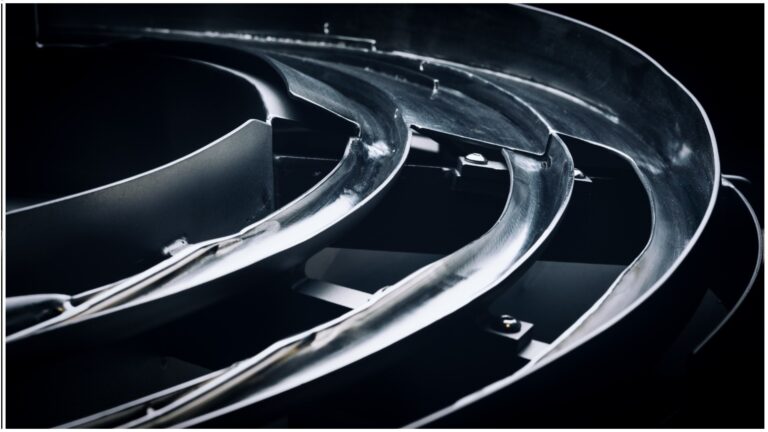

If you have chosen a feeder system from RNA, we offer you the unique added value of mapping your plant completely digitally – not statically, but dynamically! With our multiphysics simulation software Digital Feeder, we simulate the function of your plant in order to avoid cost- and time-intensive commissioning loops, which are common in feeding technology. Before the start of production, the sorting solutions we design can be tested by simulation, the optimum geometry of each individual sorting (tooling) can be determined, checked and approved. This makes RNA’s feeding systems 100% digital and reproducible. The feeding system is equipped with material-specific toolings, which can be milled or printed. These toolings can thus be produced within a few days after simulation of the bulk material behaviour and changed within a few minutes – the digital twin of your feeding system!